- Pneumatic Pipe Line-Up Clamp

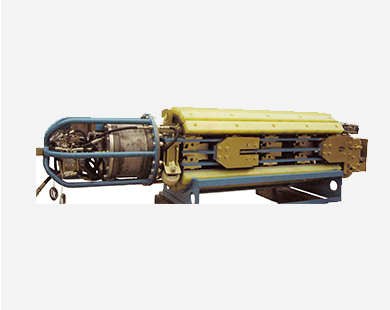

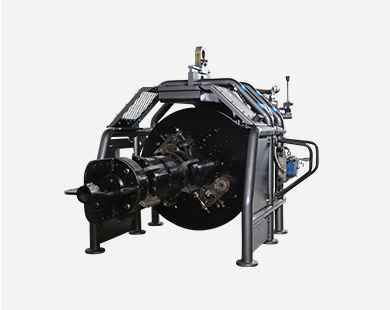

- Pipe Facing Machine

- Automatic Internal Welding Machine

- Automatic Orbital Welding Machine

- Visual Inspection Scanner

- Paywelder

- Pipeline Roller Cradle

- Pipe Bending Mandrel

- External Pipe Line-Up Clamp

- Pipe Fired Ring Heater

PFM2436

1. Internal expanding type clamping mechanism:

2. Adjustable cutter holder to ensure beveling accuracy within ±0.05mm

3. Operating control system: modular centralized control

4. SAUER DANFOSS cycloid hydraulic motor

5. Hydraulic station : diesel and electrical types

6. A variety of material adaptation: carbon steel, stainless steel, CRA

PDF Download- Specification

- You may also like

| DPFM SERIES PIPE BEVLING MACHINE | |

| Type | PFM2436 |

| Product size(L*W*H) | 2600*1800*1800 |

| Weight (KG) | 2500 |

| Applicable range | 24"-36" |

| Max. applicable wall thickness | 30mm |

| Clamping type | Internal centering hydraulic expanding mechanism: accurate centering, powerful clamping, safe and reliable |

| Bevel shape | V shape,U shape,mixed shap,combined innner and outer bevel shape |

| Beveling accuracy | Dimension tolerance ±0.05mm,Angle tolerance±0.5", Ra1.6 |

| Beveling efficiency (including auxiliary time) | Less than 3 mins |

| Hydraulic motor | SAUER DANFOSS |

| Cutting speed | 105m/min |

| Cutting depth | 0.2mm-0.6mm |

| Cutter | SANDVIK/WALTER |

| Operation system | Expanding/release, fast forward/fast backward, working feed, speed adjustment of working feed |

| Working pressure | Operating pressure:10-12MPa;Cutting pressure:0-18MPa |

| Hydraulic power unit | Motor type/Diesel type |

| DHPS-E(O) SERIES MOTOR TYPE (DISEL TYPE) HYDRAULIC POWER UNIT | ||||

| Type | DHPS-E0680 | DHPS-O0680 | ||

| Product size(L*W*H) | 2430*1250*1180/2530*1150*1900 | |||

| Weight (KG) | 1500 | |||

| Applicable pipe beveling machine | DPFM0612、DPFM1224、DPFM2442、DPFM4060、DPFM6080 | |||

| Hydraulic oil tank capacity | 500L | |||

| Fuel tank capacity | None | 150L | ||

| Primary motor | 55KW | None | ||

| Auxiliary motor | 7.5KW | None | ||

| Engine | None | 125HP | ||

| Primary pump | A3H180 from Yuken in Japan | |||

| Auxiliary pump | A10 from Yuken in Janpan | |||

| Electric control system | Design ingress protection degree IP65, electric control components from world-class brand | |||

| Flexible connection | Remote control handle (including 20m cable),power output hose(20m) | |||

| Others | Oil discharge cooling system of oil pump, oil temperature alarm, motore overloading protection | Oil discharge cooling system of oil pump, indicators of oil temperature, water temperature and rotation speed | ||

Pipe facing machine maintenance:

Daily check

- Daily inspection and maintenance of operation valves

- Lubrication of relevant parts area

- Daily inspection and maintenance of hydraulic components

- Daily inspection and maintenance of cutting tool assmebly

Regualar check

- Regular equipment check and maintenance shall be carried out for clearing fault.

- Regular lubrication of pipe facing machine is required

Pipe facing machine storage:

-When the equipment is stored, to ensure its performance remains unaffected by rust, a sufficient amount of anti-rust oil should be applied to its surface.

Pipe facing machine maintenance: