- Pneumatic Pipe Line-Up Clamp

- Pipe Facing Machine

- Automatic Internal Welding Machine

- Automatic Orbital Welding Machine

- Visual Inspection Scanner

- Paywelder

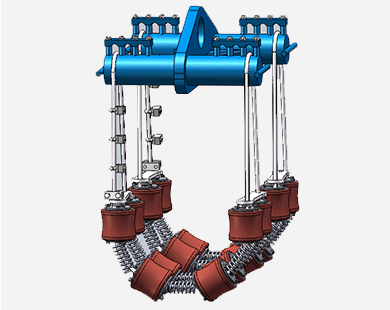

- Pipeline Roller Cradle

- Pipe Bending Mandrel

- External Pipe Line-Up Clamp

- Pipe Fired Ring Heater

MPS-H100

1.Reduce defect rate and maintaiance cost

2.Our paywelder has 11.2% improvement in efficiency compared with similar products

3.Paywelder rigid straight connecting of engine, generator and hydraulic pump

4.Patented design of hydraulic clutch system to save fuel cost

PDF Download- Specification

- You may also like

| Model | MPS-H100 | |

| Operating Weight | 11500Kg | |

| Overall Dimensions (L*W*H) | 5500*2600*3050mm | |

| Engine | Type | Cummins 6BTA5.9-C180 Turbo-charged, Water Cooling |

| Power | 132KW (at power generating condition: 121KW/1500rpm) | |

| Rotating Speed | 2200 rpm | |

| Generator | Type | Faraday Generator FD3C (50hz/1500rpm) |

| Rated Power | 100kw | |

| Rated Capacity | 125kva | |

| Output Type | Three phases 380v | |

| Operating Format | Pressure/ Flux | 25mpa/189 L/Min |

| Traveling | Indoor hand & foot synchronization joy stick | |

| Generating | Indoor positioning joy stick | |

| Lifting | Outdoor joy stick | |

| Travel | Travel Speed(Front & reverse) | 2.8/4.6km/h (two shifts ,continuously variable transmission) |

| Grade ability | 30° | |

| Ground Pressure | 33/25 Kpa 39/32 Kpa | |

| Chassis | Minimum Ground Clearance | 490mm |

| Track Shoe Width | 500mm/600mm | |

| Cantalever Lift | Type | Hydraulic 360°swing ,telescopic boom |

| Max Lifting capacity | 3200kg | |

| Crane Radius | 2100-5320mm | |

| Pressure /Flux | 20mpa/25L/Min | |

| Main Carrying Capacity | DC400 4 units of Lincoln welding machine; 1 unit of 7.5KW air compressor and 4 units of handwheel polisher (Factory setting: this equipment doesn't carry above items) |

|

“MPS-H Series” all-hydraulic paywelder is the special pipeline construction equipment, which has power saving, high efficiency and powerful cross-country performance, be able to perform in severe working conditions such as swamp, desert, ect, also it functions of all generating, traveling, welding, lifting ability

Main features:

Patented design of rigid straight connecting of engine, generator and hydraulic pump

Powerful cross-country performance supported by 10T excavator chassis with ship type platform frame and 91KN powerful traction

Compared with similar products, our paywelder has an 11.2% improvement in efficiency, also cantilever crane equipped an independent hydraulic system, full rotating 360°ability

Comfortable operating spacei in paywelder cab:safe and low vibrating of YF-3opearting cab

Reducing maintenance cost:incorporate engine, generator with hydraulic pump

Convenient turning operation :paywelder platform is equipped with the built-in lifting hook, easy hoisting and shipping

Engine :Cummins 6BTA series engines, making it suitable for harsh working condition such as high temperature, high cold temperature and high elevation

Powerful & Stable traction: depending on powerful traction, the paywelder can maneuver easily on uneven terrin, hilly and wetland areas, it has excellent off road performance

Gas bottle mounting frame: The frame can be installed 4~6 gas bottles of oxygen, acetylene, carbon dioxide etc.

It adopts the features of reliable fixation, easy disassembly, rational layout and save space.